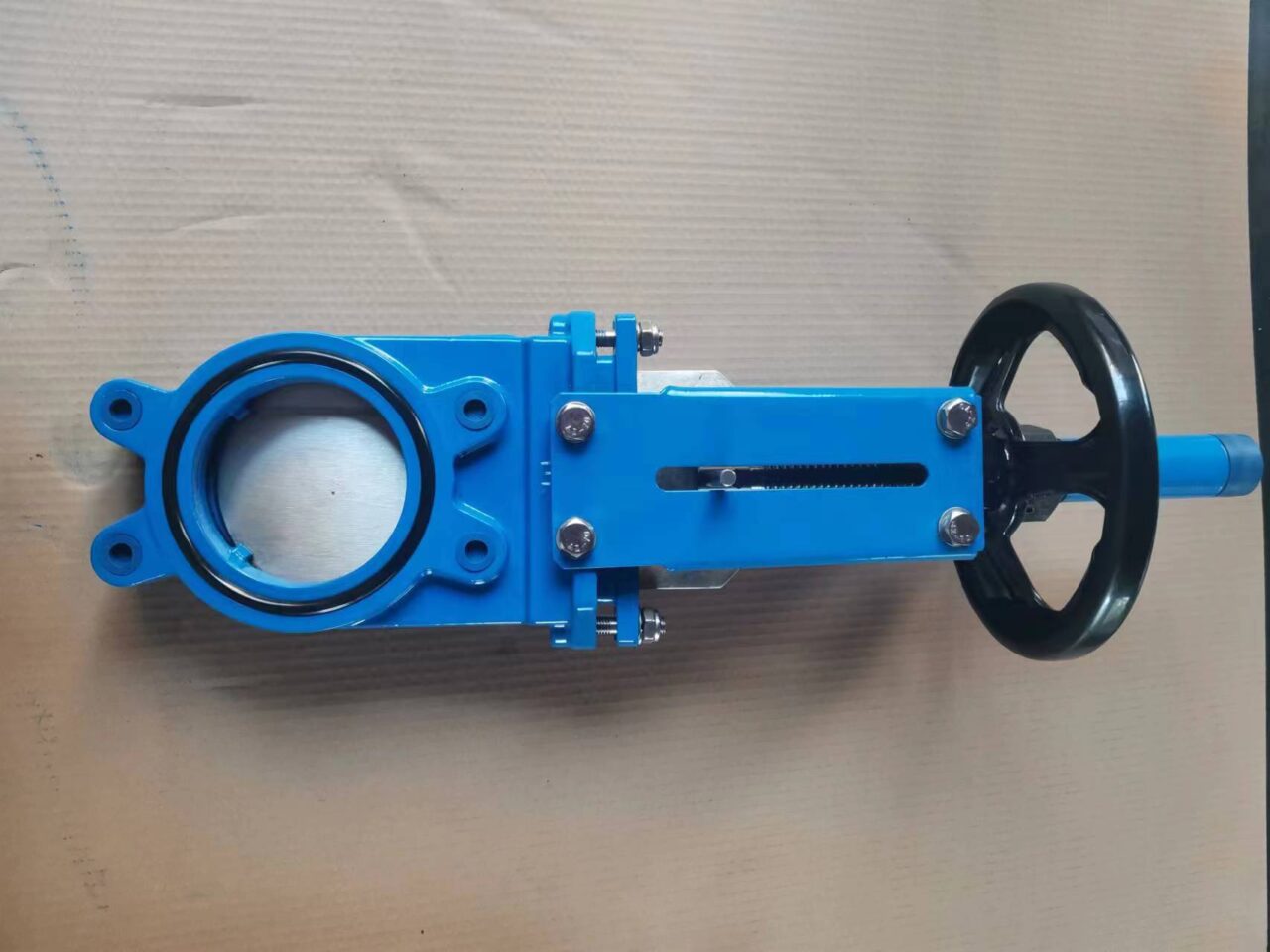

Knife gate valve product pre factory inspection – HB2412 order

When it comes to industrial valves, quality and reliability are key factors to consider. This is especially true for knife gate valves, which are commonly used in industries such as mining, pulp and paper, wastewater treatment, and more. To ensure that the knife gate valves meet the required standards and specifications, a pre-factory inspection is often conducted.

Recently, a pre-factory inspection was carried out for the HB2412 order of knife gate valves. This particular order was for a large quantity of valves to be used in a new wastewater treatment plant. The inspection was conducted to ensure that the valves met the necessary quality standards and specifications before they were shipped out to the customer.

During the inspection, the valves were carefully examined for any defects or damage. The dimensions and materials of the valves were checked to ensure that they met the required specifications. The operation of the valves was also tested to ensure that they functioned properly and could withstand the harsh conditions they would be exposed to in the wastewater treatment plant.

Additionally, the valves were inspected for any signs of corrosion or wear that could affect their performance. Any issues that were identified during the inspection were addressed and resolved before the valves were approved for shipment.

Overall, the pre-factory inspection for the HB2412 order of knife gate valves was a success. The valves were found to meet the necessary quality standards and specifications, ensuring that they would perform effectively in the wastewater treatment plant.

In conclusion, pre-factory inspections are an important step in ensuring the quality and reliability of industrial valves such as knife gate valves. By conducting thorough inspections, manufacturers can identify and address any issues before the valves are shipped out to customers, ultimately leading to better performance and longevity of the valves.